Yes, Tesla uses job order costing. This means that costs are assigned to specific jobs, and the cost of each job is tracked separately.

This allows Tesla to see how much each job costs and to compare the cost of different jobs.

Tesla Service Hourly Rate

Tesla Service Hourly Rate If you’re a Tesla owner, you know that maintaining your vehicle can be expensive. One of the most important aspects of ownership is taking your Tesla to get serviced regularly.

While Tesla offers many services for free, there are some that come with a fee. One of these is the hourly service rate. Here’s everything you need to know about the Tesla service hourly rate.

The first thing to know is that the hourly service rate varies depending on which country you live in. In the United States, the current hourly service rate is $180 per hour. This may seem like a lot, but it’s actually quite reasonable when you compare it to other luxury car brands.

For example, Bentley charges $200 per hour and Rolls-Royce charges $300 per hour for their services. So, when it comes to pricing, Tesla is actually on the lower end. One thing to keep in mind is that the hourly service rate only applies to certain services.

If you need something major done to your vehicle, such as a battery replacement or an engine repair, then you’ll be charged a flat fee for those services instead of an hourly rate. However, for smaller jobs like routine maintenance or software updates, you will be charged by the hour. Another important thing to note is that not all Tesla stores charge the same hourly service rate.

Some stores may have a higher rate due to their location or because they offer additional services beyond what’s included in the standard package. So, if you’re considering taking your Tesla in for service, be sure to call around and compare rates before making your final decision.

Where are Tesla Cars Made?

Tesla cars are made at the Tesla Factory in Fremont, California. The factory is located on a 7 million square foot site and employs over 10,000 workers.

The factory has been producing cars since 2012 and has produced over 500,000 cars to date.

Whats the Cheapest Tesla?

There are a few things to consider when trying to find the cheapest Tesla. The first is the model of Tesla you are looking at. There are three main models: the Model S, Model X, and Model 3.

The Model S is generally the most expensive, followed by the Model X, with the Model 3 being the most affordable. However, prices can vary depending on which features and options you choose. Another thing to consider is how you plan to finance your Tesla.

If you plan to lease or take out a loan, there will be additional costs associated with that. You may also get a discount if you purchase your Tesla outright in cash. Finally, keep in mind that Teslas are still luxury vehicles and as such, they come with a higher price tag than most other cars on the market.

With that said, there are ways to get a cheaper Tesla if you know where to look and what to consider.

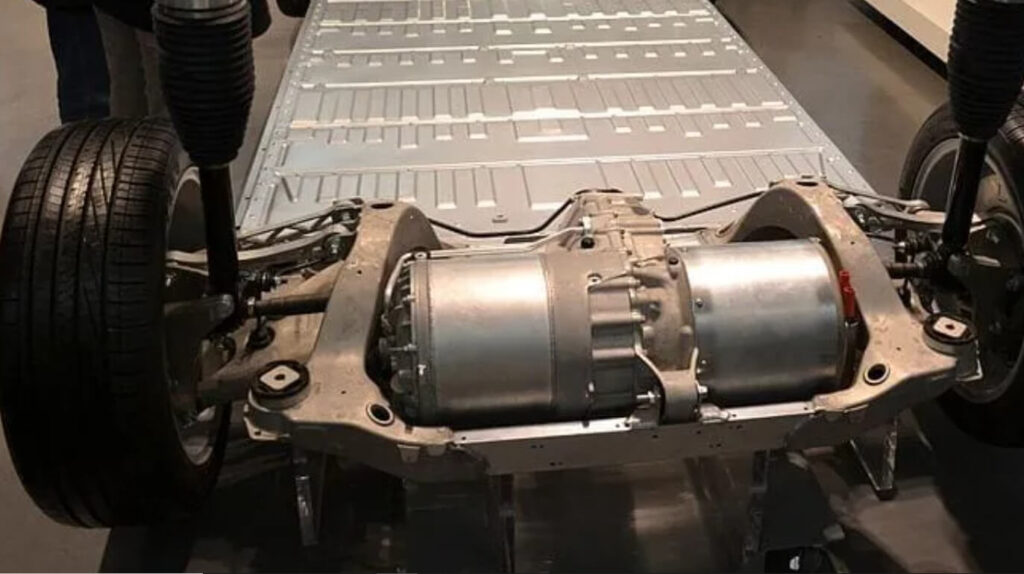

Who Supplies Tesla Batteries?

Tesla is one of the leading manufacturers of electric vehicles, and their batteries are a crucial part of these cars. While Tesla produces their own batteries for some of their models, they also source batteries from suppliers. Panasonic is one of Tesla’s primary battery suppliers, and they produce the cylindrical 18650 cells that are used in Tesla’s Model S and X cars.

LG Chem and Samsung SDI are two other companies that supply batteries to Tesla. These companies both make prismatic cells, which are used in the Model 3. Tesla has high standards for the quality of their batteries, so their suppliers must meet rigorous specifications.

The cells must have a long lifespan, be able to withstand high temperatures, and perform well under extreme conditions. As electric vehicles become more popular, demand for Tesla batteries will continue to increase. This means that finding reliable suppliers is essential to ensuring that production can keep up with demand.

What Companies Would Use Job Order Costing?

Job order costing is a system used by businesses to track the costs associated with specific jobs. This information can be used to price future jobs, track efficiency and performance, and make decisions about where to allocate resources. Companies that typically use job order costing include those that manufacture products or provide services to customers on a per-job basis.

For example, a company that makes custom furniture would use job order costing to track the cost of materials and labor for each piece of furniture they produce. Similarly, a company that provides landscaping services may use job order costing to estimate the cost of a new project for a customer. In general, companies that need to track costs associated with individual projects or jobs are good candidates for using job order costing.

This system can be particularly helpful in industries where there is a lot of variation in the products or services being produced. By tracking costs carefully, companies can ensure they are pricing their products and services accurately and making profits on each job.

What Companies Use Job Order Costing And Process Costing?

In job order costing, each individual job is tracked separately and costs are assigned to each job. This system is used when companies produce products or provide services that are unique and not part of a mass production process. Process costing, on the other hand, assigns costs to homogeneous units of output that are produced in a continuous mass production process.

Companies that use process costing typically manufacture large quantities of standardized products.

The Flow of Costs: Job Order Costing + Journal Entries.

Conclusion

Tesla does use job order costing, as evidenced by the fact that they track direct labor and manufacturing overhead costs. This allows them to allocate these costs to specific vehicles, which is necessary for accurate costing.

However, Tesla also uses activity-based costing to track indirect costs, which provides a more comprehensive view of the cost of producing a vehicle.