The belt tensioner is a vital component of the engine’s serpentine belt system, and when it fails, the engine will not be able to run. There are a few reasons why a belt tensioner might fail, but the most common is simply age and wear. If the tensioner won’t move at all, it needs to be replaced.

If your belt tensioner won’t move, it may be due to a few different issues. First, check to see if the tensioner pulley is seized. If it is, you’ll need to replace the tensioner.

Next, check the serpentine belt for any damage or wear. If the belt is damaged, it will need to be replaced. Finally, check all of the accessory drive belts for proper tension and alignment.

How to Loosen Tensioner Pulley Without Tool?

When it comes to working on your car, there are a lot of things that you can do without any special tools. One of those things is loosening the tensioner pulley. This can be a difficult task if you don’t know how to do it, but luckily, we’re here to help!

To start, you’ll need to locate the tensioner pulley. This is usually located near the engine, and it may have a cover over it. Once you’ve found it, you’ll need to put your hand on the center of the pulley and push down.

As you do this, you should hear a clicking sound. This indicates that the tensioner has been released and that you can now remove the belt. If for some reason the tensioner doesn’t release when you push on it, don’t worry!

There’s another way to loosen it without using any tools. Simply take a piece of string or wire and wrap it around the center of the pulley. Make sure that the string is tight so that it won’t slip off when you pull on it.

Once the string is in place, simply pull on one end until the tensioner releases. You may need to use a little bit of force, but be careful not to break the string! Once the tensioner is loose, carefully remove the belt and then unwrap the string from around the pulley.

And that’s all there is to it!

Serpentine Belt Tensioner

A serpentine belt tensioner is a device that keeps the serpentine belt tight and in proper alignment. The tensioner is mounted on the engine and has a spring-loaded arm that puts pressure on the belt. As the engine turns, the arm moves back and forth, keeping the belt tight.

The serpentine belt is one of the most important parts of your car’s engine. It’s responsible for driving all of the accessories like the alternator, power steering pump, and air conditioning compressor. If it breaks or comes loose, those accessories will stop working and your car will quickly overheat.

That’s where the serpentine belt tensioner comes in. This vital component ensures that your serpentine belt stays tight and in proper alignment while you’re driving. Without it, your car would be at risk of serious damage or even breaking down entirely.

If you think your serpentine belt tensioner may be failing, watch out for these common signs: squealing noises from under the hood, difficulty turning the steering wheel, dimming headlights, and an overheating engine. If you notice any of these issues, take your car to a mechanic right away to have it checked out.

Can a Bad Belt Tensioner Cause Vibration?

A belt tensioner is a device that helps keep your vehicle’s engine belts tight, preventing them from slipping or becoming loose. If your vehicle’s belt tensioner is not working properly, it can cause the engine belts to vibrate, which can lead to all sorts of other problems.

In some cases, a bad belt tensioner can even cause engine damage.

How to Check a Belt Tensioner?

When it comes to maintaining your car, there are a lot of different things that you need to keep an eye on. One of the most important parts of your car is the belt tensioner. This piece keeps your belts tight so they can do their job properly.

If the tensioner is loose, it can cause all sorts of problems with your car. Luckily, checking the belt tensioner is a pretty easy process that anyone can do. To check the belt tensioner, you’ll first want to locate it.

It’s usually located near the front of the engine, and it will have a pulley attached to it. Once you’ve found it, you’ll want to use a wrench to loosen the nut that holds the pulley in place. After you’ve loosened the nut, you should be able to move the pulley back and forth.

If there’s any movement more than about an inch or so, then your belt tensioner is too loose and needs to be tightened up. To do this, simply tighten the nut back down until there’s no more play in the pulley. You may need to use a socket wrench or impact wrench to get enough torque on the nut.

Once it’s tight, test it out by starting up your engine and moving various components such as your power steering pump or alternator back and forth by hand. If there’s still too much play, then repeat the process until everything feels snug.

V-Belt Tensioner

A V-Belt Tensioner is a device that is used to tension or take up the slack in a v-belt. The most common type of v-belt tensioner is a spring loaded idler pulley. The other type of tensioner is an adjustable pivot arm.

V-Belt tensioners are used on all kinds of machinery, from lawn mowers to car engines. V-Belt tensioners work by applying pressure to the v-belt, which in turn makes the belt tighter. This process takes up any slack in the belt and ensures that it runs smoothly.

When properly adjusted, a v-belt tensioner will keep a belt running at peak efficiency for its entire lifespan.

Belt Tensioner Assembly

Belt tensioners are an important part of any engine, as they keep the belts tight and prevent them from slipping. A belt tensioner assembly consists of a pulley, spring, and bracket that work together to keep the correct amount of tension on the belt. Over time, however, these components can wear out and need to be replaced.

If you notice your engine’s belts starting to slip or squeal, it’s a good indication that your belt tensioner assembly needs to be checked. Replacing a worn out or damaged belt tensioner is relatively simple and can be done with just a few tools. In most cases, you’ll only need a socket wrench and some replacement nuts and bolts.

Once you have the old belt tensioner assembly removed, simply install the new one in its place. Be sure to follow the manufacturer’s instructions for proper installation. With the new assembly in place, tighten down all of the bolts and check that the belts are properly tight before starting up your engine.

Is the Tensioner Pulley Supposed to Move?

If your car’s engine is making a squealing noise, it could be the tensioner pulley. The tensioner pulley is responsible for keeping the belt tight so that it can properly drive the accessories. If the pulley moves too much, it can cause the belt to slip and make noise.

While it is normal for the tensioner pulley to move a little bit, if it is moving excessively, it may need to be replaced.

Drive Belt Tensioner Pulley

A drive belt tensioner pulley is a small, simple device that keeps your car’s engine running smoothly. The tensioner pulley is located on the front of the engine, just behind the fan belt. It consists of a small wheel that is attached to a spring-loaded arm.

The arm puts pressure on the belt, keeping it tight against the pulleys. The drive belt tensioner pulley is an important part of your car’s engine because it ensures that the belts are tight enough to transfer power from the crankshaft to the accessories, but not so tight that they slip or break. Over time, the springs in the tensioner can weaken, causing the belts to become loose and eventually leading to engine problems.

If you think your car’s drive belt tensioner might be going bad, there are a few signs to look for: squealing noises from under the hood, cracks or wear on the belts themselves, or vibration in the steering wheel while driving. If you notice any of these symptoms, take your car to a mechanic for inspection as soon as possible.

Is the Belt Tensioner Supposed to Move?

The belt tensioner is a vital component in keeping the engine running smoothly. Its purpose is to keep the belt tight so that it can transfer power from the crankshaft to the various components in the engine. The tensioner itself is mounted on bearings and uses either a spring or hydraulic pressure to maintain tension on the belt.

Over time, the bearings and other parts of the tensioner can wear out, causing it to loosen and allow more slack in the belt. This can cause all sorts of problems, including engine vibration and noise, as well as decreased power and efficiency. In some cases, it can even lead to catastrophic engine failure.

The good news is that most modern cars have a self-adjusting tensioner that takes up any slack automatically. However, these can also wear out over time and may need to be replaced. If you’re not sure whether your car has a self-adjusting tensioner or not, it’s best to consult your owner’s manual or take it to a qualified mechanic for inspection.

Can a Belt Tensioner Seized Up?

A belt tensioner is a device that helps to keep your car’s engine accessories properly aligned and functioning. Over time, however, a belt tensioner can become seized up, making it difficult for your engine accessories to stay in proper alignment.

If you notice that your car’s engine accessories are starting to misalign or function improperly, it’s important to have a mechanic check your belt tensioner for signs of seizing.

How Do You Release Tension on a Tensioner?

If your car has an automatic belt tensioner, it is important to know how to release the tension on the belt. This can be done by using a ratchet and socket to loosen the tensioner pulley bolt. Once the bolt is loosened, you can then rotate the tensioner pulley by hand to release the tension on the belt.

If your car has a manual belt tensioner, you will need to use a wrench to loosen the nut that holds the tensioner in place. Once the nut is loosened, you can then rotate the tensioner by hand to release the tension on the belt.

How to release tensioner pulley?

To release the tensioner pulley on a vehicle’s serpentine belt or accessory drive belt, you’ll typically need to use a wrench or a dedicated tensioner tool. Place the wrench or tool on the tensioner pulley’s bolt or designated tensioner arm and rotate it in the direction that relieves tension on the belt.

This will allow you to remove or replace the belt and then release the tensioner to maintain proper belt tension. Consult your vehicle’s service manual for specific instructions and the correct direction to rotate the tensioner, as it can vary by make and model.

Why is My Belt Not Spinning?

If your dryer’s belt is not spinning, there are a few possible explanations. The first thing to check is whether the belt is still intact and attached to both the drum and the motor. If it has come loose from either one of these, it will need to be reattached.

Another possibility is that the motor itself may have burned out and will need to be replaced. Finally, there could be an issue with the pulleys that the belt wraps around. If they are seized up or broken, they will also need to be replaced.

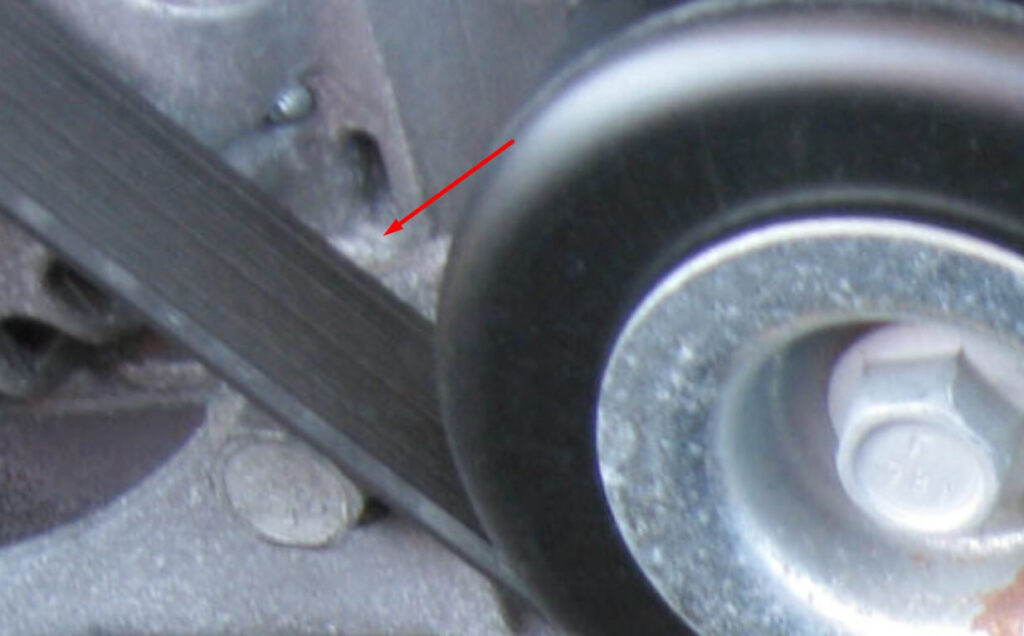

Belt tensioner/ seized not moving/ How to get it to move

Conclusion

If your belt tensioner won’t move, it may be due to a few different things. The first thing you should check is the bolt that holds the tensioner in place. If this bolt is too tight, it can cause the tensioner to freeze up.

Another possible reason for a frozen tensioner is if the spring inside the tensioner has broken. This spring is what provides the tension on the belt, so if it’s broken, the tensioner won’t work properly. Finally, if your engine is overheating, this can also cause the belt tensioner to seize up.

If you’re not sure what’s causing your belt tensioner to freeze, it’s best to take it to a mechanic so they can diagnose the problem and fix it for you.